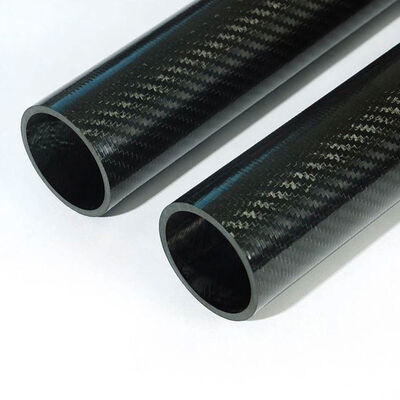

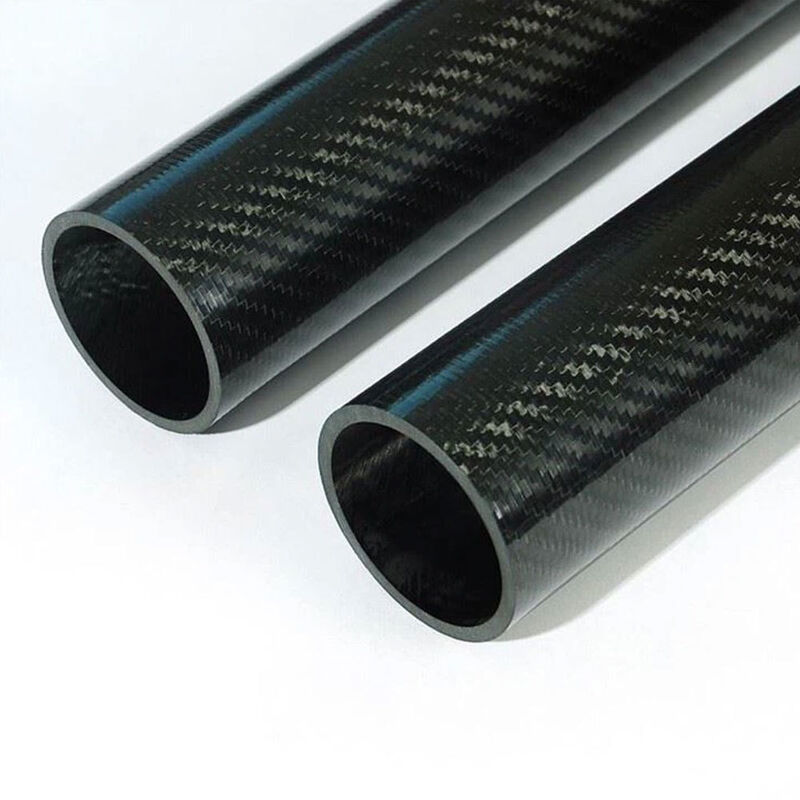

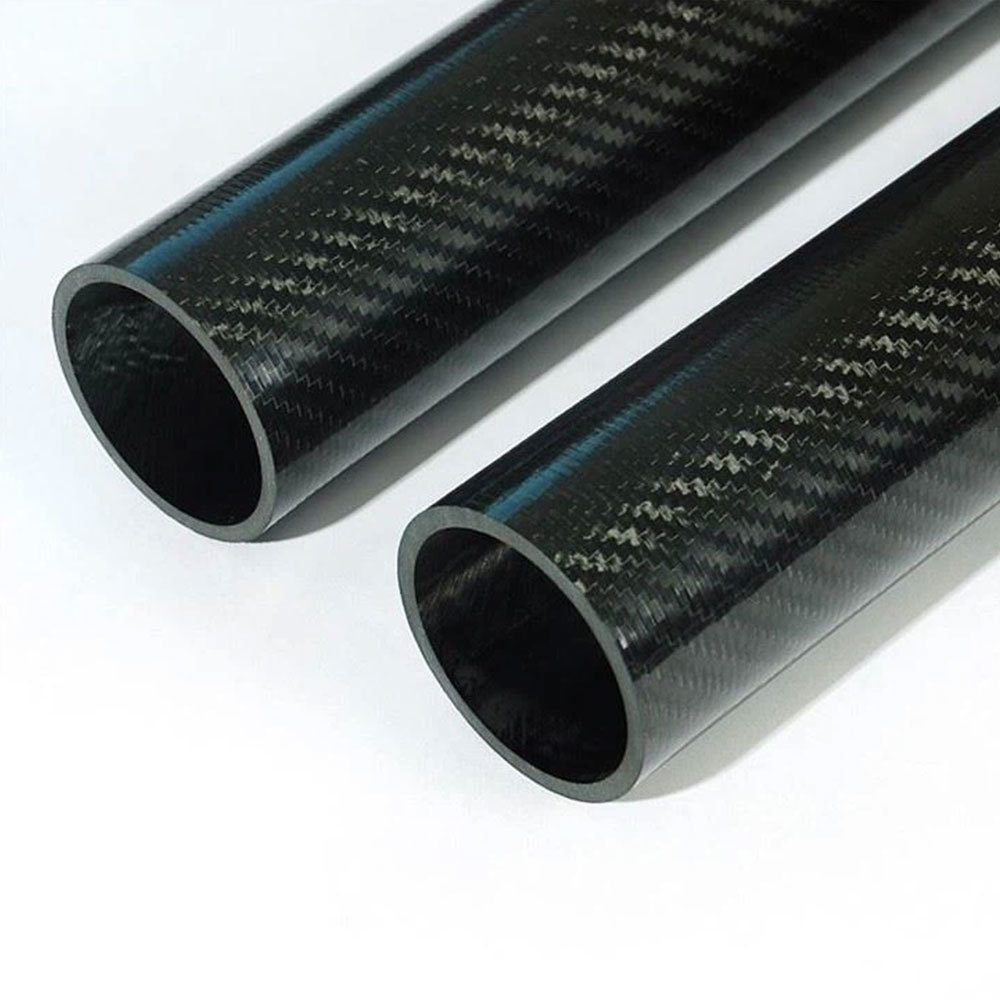

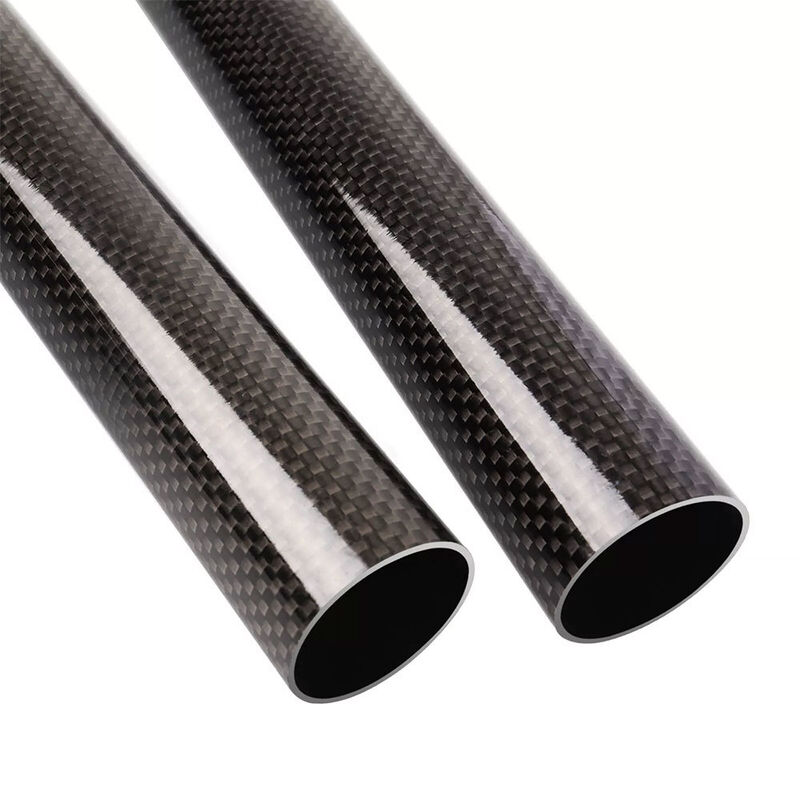

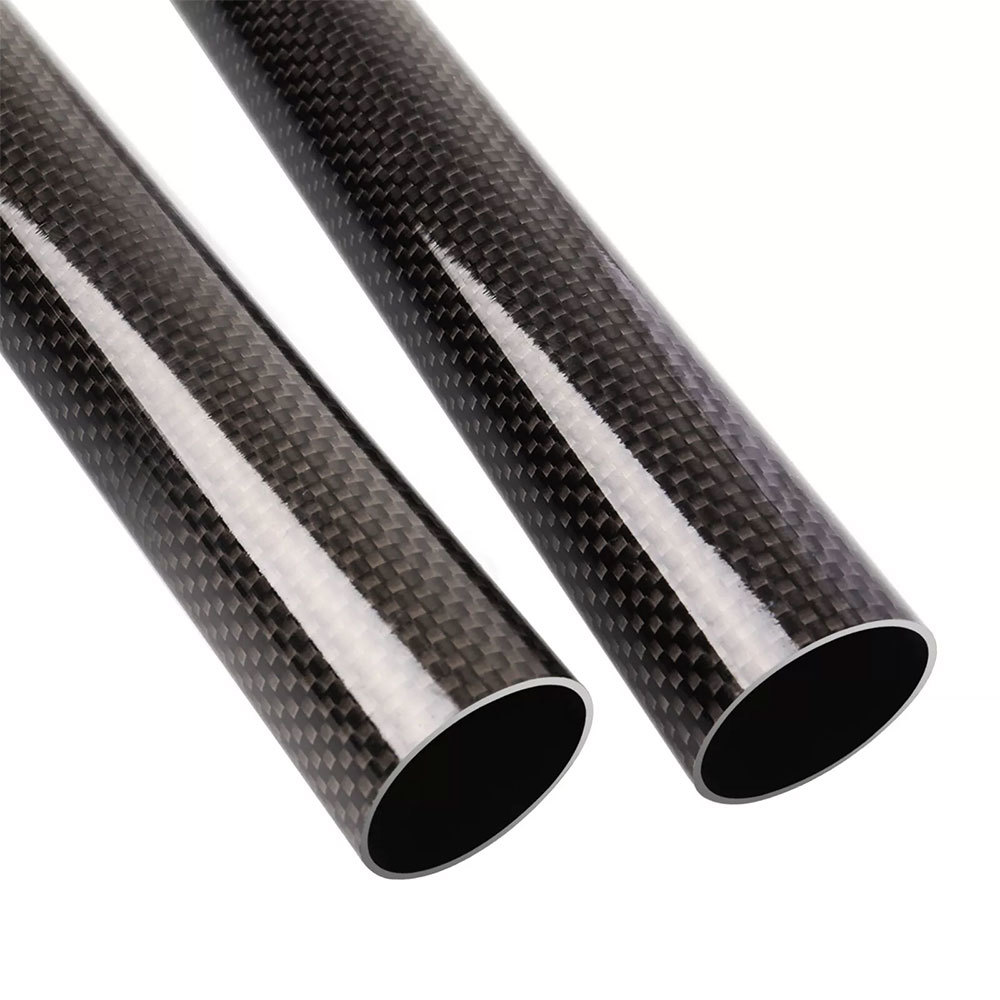

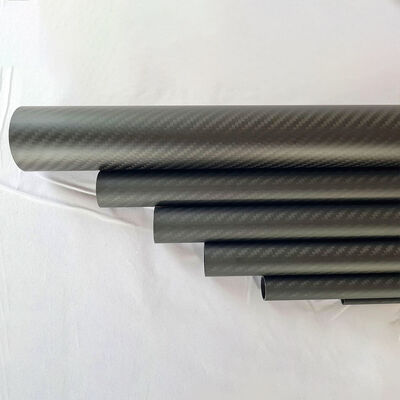

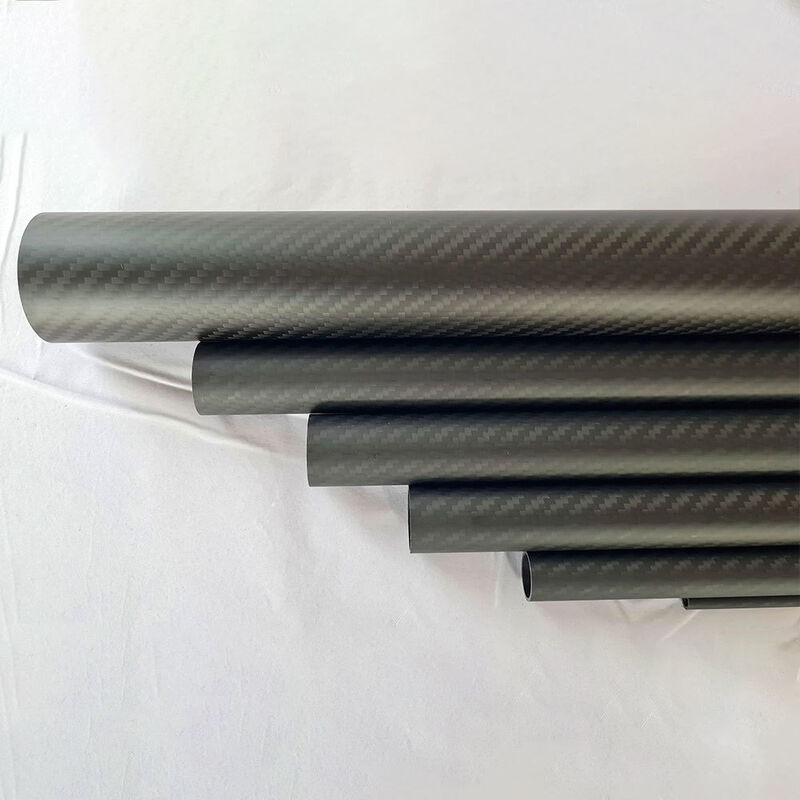

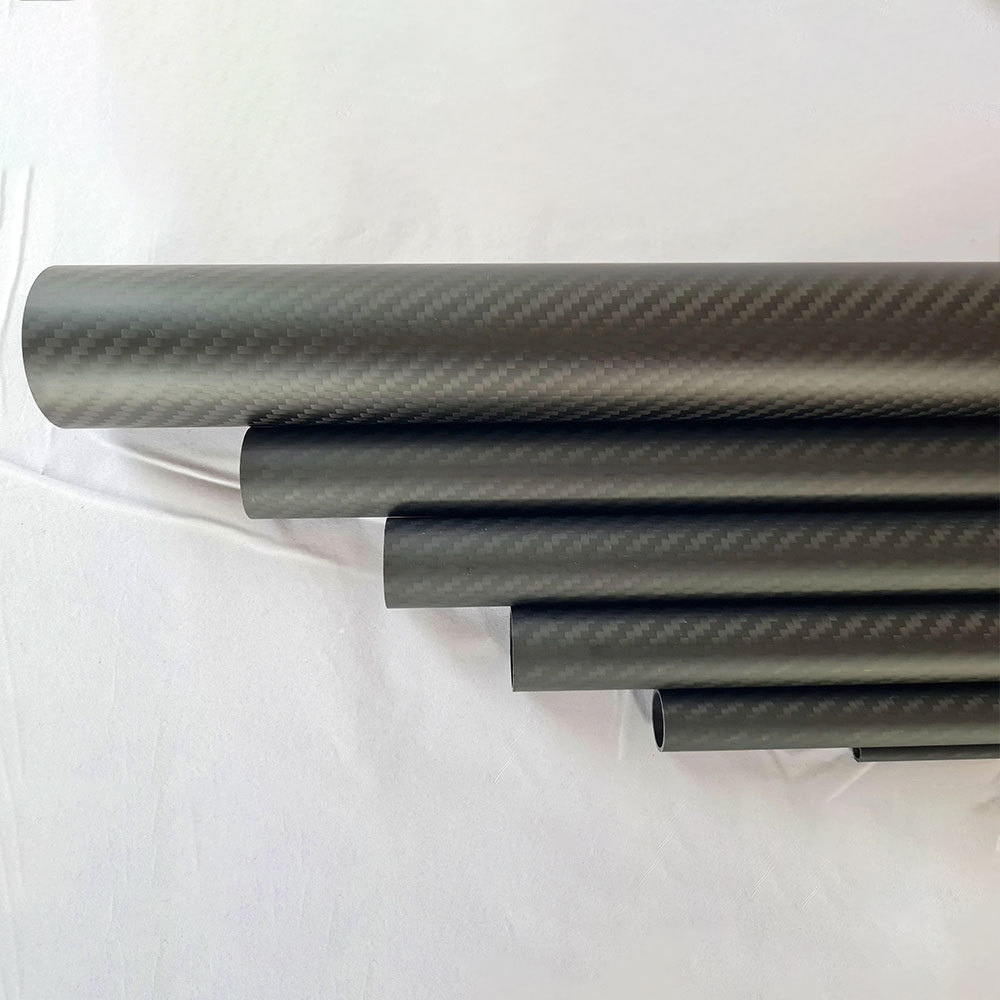

고정밀 24*22*1000mm 탄소 섬유 튜브 - 고성능 & 경량

메시지를 남겨주세요

곧 다시 연락 드리겠습니다!

귀하의 메시지는 20-3,000 자 사이 여야합니다!

귀하의 메시지는 20-3,000 자 사이 여야합니다!

이메일을 확인하십시오!

이메일을 확인하십시오!

제출

정보가 많을수록 커뮤니케이션이 향상됩니다.

씨

- 씨

- 부인

승인

성공적으로 제출되었습니다!

곧 다시 연락 드리겠습니다!

승인

메시지를 남겨주세요

곧 다시 연락 드리겠습니다!

귀하의 메시지는 20-3,000 자 사이 여야합니다!

귀하의 메시지는 20-3,000 자 사이 여야합니다!

이메일을 확인하십시오!

이메일을 확인하십시오!

제출